Mass Gravity Retaining Walls

2021

DIST. REASI, KATRA - JAMMU & KASHMIR - India

Indian Railways-USBRL

AFCONS Infrastructure Ltd

Maccaferri / KRCL

REINFORCED SOIL WALL AT ABUTMENT OF BRIDGE- 43 IN REASI, J&K

Problem

Udhampur-Srinagar-Baramulla Rail link Project (USBRL) is a project of national importance under Indian Railways with a view to provide an alternative and a reliable transportation system to Jammu & Kashmir. 272 Km long railway line from Udhampur to Baramulla joining the Kashmir valley is proposed which will entail the most challenging works undertaken post-independence by Indian Railways. The alignment of USBRL involves construction of a large number of tunnels and bridges in highly rugged and mountainous terrain with most difficult and complex Himalayan geology. At one of the locations near Katra (Chenab bridge), there was a requirement of earth retaining structure at Bakkal (Jammu) side for abutment of bridge no 43 to support the installation cranes for world’s highest railway bridge from Bakkal (Jammu side) to Kauri (Srinagar side) at Chenab river in the Reasi district of Jammu and Kashmir India. The client was looking for a system which is economical and fast to construct.

Solution

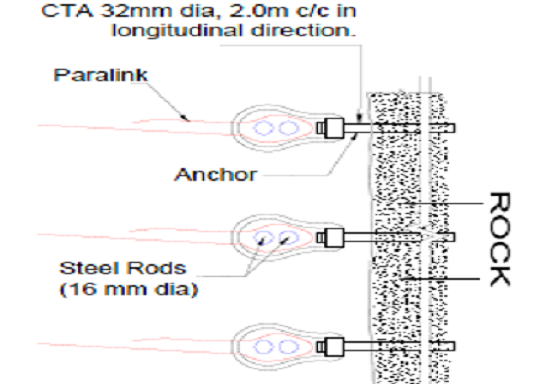

Based on the site conditions and specific requirements of the client, Terramesh units made of gabion fascia along with an integrated tail as reinforcement of length 2m which is made of mechanically woven, double twisted, hexagonal shaped steel wire mesh was used. On the upper reaches of the structure, Green Terramesh units consisting of double twisted hexagonal shaped steel woven wire mesh along with a biodegradable erosion control blanket and a welded mesh panel with three steel tie rods were installed. For composite soil reinforcement system on which cranes could work, high strength flexible geogrids made of polyester core with polyethylene coating, ParaLink were installed as a primary reinforcement. Drainage composite, MacDrain W was used for drainage purposes between two different fills. Polyester needle punched non woven geotextile, MacTex was used as a filter media behind gabion facia units and wrapped around PVC pipe which allowed free movement of water and prevented backfill soil from entering in the voids between stone filling. Further, continuous threaded anchors of min. 3m length were embedded into the rock strata. Paralink was connected with anchors.

Used Products

加筋格宾

马克菲尔 Terramesh® 系列包括用于建造机械稳定土 (MSE) 结构和加固土坡 (RSS) 的不同面层选项。 加筋格宾由双绞合金属网(网孔规格8X10)构成,可就地随时组装。面板及盖板是一块连续的网板,无需现场切割操作。 Terramesh® 装置由优质钢丝和聚合物涂层 (PolimaView

无纺土工布

无纺土工布是由合成纤维组成的扁平织物结构,通过针刺或热处理随意组装而成;主要用于实现分离、过滤和保护功能,并且是许多其他复合材料与土工合成材料组合的基础。 它们的质量和性能会因纤维长度、使用的聚合物、组装过程等而有所不同; 土工合成材料是最常见的一种。View